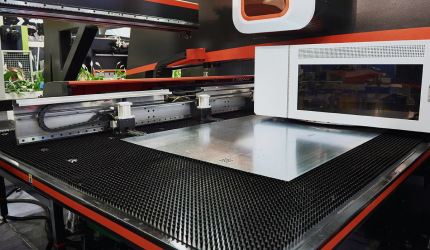

Turret Punch Press: Three machines made by world-renowned Amada are capable of producing high-quality turret punch press services for your project. Our Machines include: the Amada Pega 5 ft., the Amada Vipros 5 ft. and the Amada EM 5 ft.

Our Process: Our Amada flywheel punch press turret Machines decrease snags and hangups when processing metal in the machine. Each in-house part is designed in Solidworks and transformed into AutoCAD to tool the fit of the DXF for the turret.

The DXF is then taken from the AutoCAD software and sent to the L3 laser workstation, where an operator uses the program file to define tools to use, double checks quality and runs the turret.

Production Metrics:

- The cost of turret services is hourly.

- Our E2 quoting system will give an approximate cost for your particular part, and as always, can be discussed with a member of our team for more clarity and insight into our processes and pricing.

- Make Span

- This will vary and depend on the project submission, as well as material selection. For example, the shear accomplishes a job or project for a 1- Pearce P94 Panels out of prepared blanks. The make span for this particular project will take around 45 minutes to accomplish.

- Total inventory

- Total inventory varies per order and depends on the material needed. Our materials manager will order sheets or blanks for the job and create a flow time from the total inventory and make span depending on the part submit and material.

- It takes the shear operator around 45 minutes to shear 10 blanks resulting in a flow time of about 1.5 hours with setup and part check.

- Utilization- Our machine can run 8 hours a day on 1 shift with overtime as needed. The Average Daily utilization is around 20% for an 8-hour day. Utilization can change to around 28 to 30 percent if the machine was being used nonstop during a first shift.